Chinese scientists create solid-state DUV laser sources for chipmaking tools

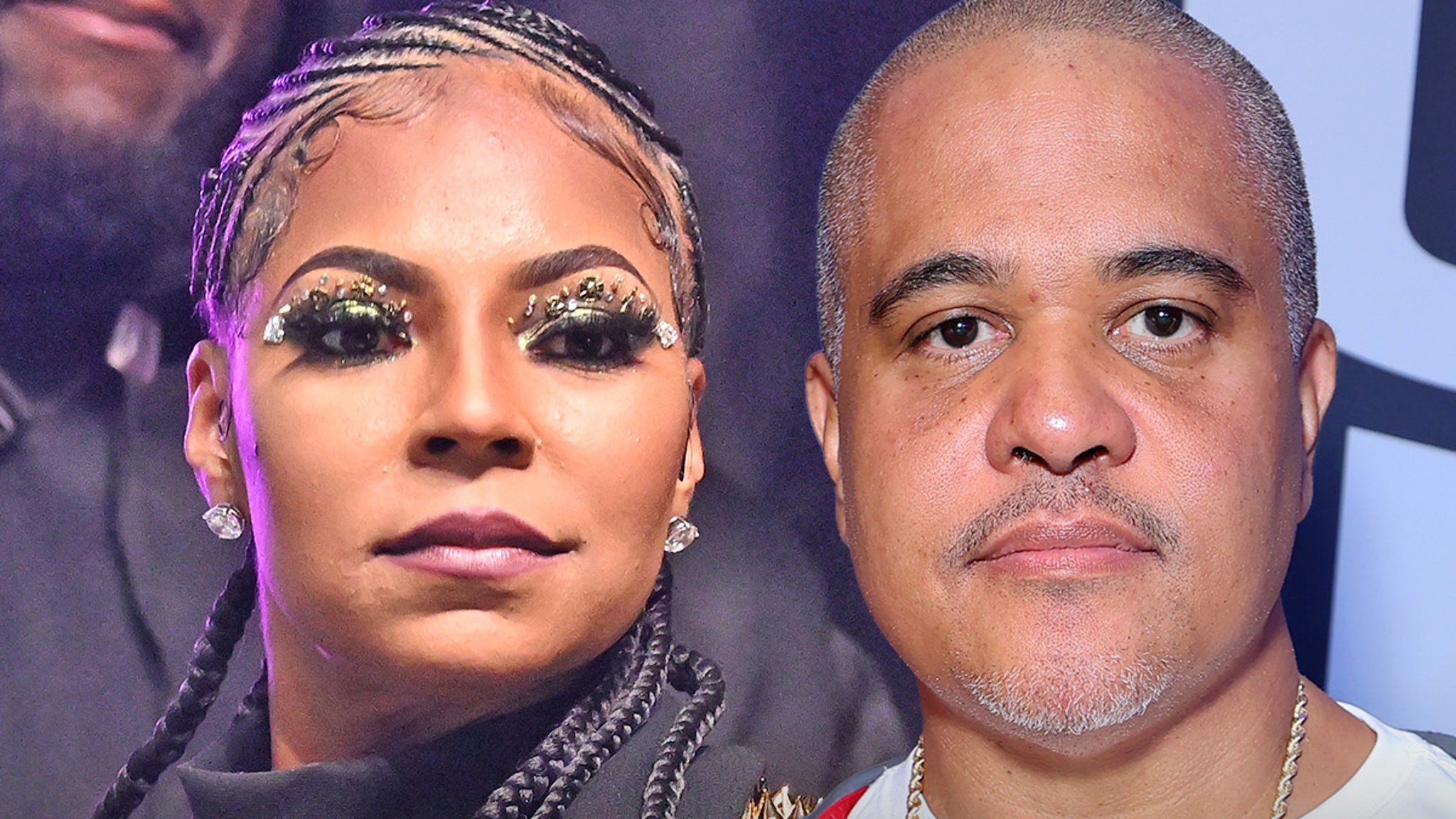

According to SPIE, researchers from the Chinese Academy of Sciences (CAS) have created a solid-state deep ultraviolet (DUV) laser emitting coherent 193-nm light used for semiconductor photolithography in a lab. If the light source technology can be scaled, this device could be used to build lithography tools that make chips using advanced process technologies. However, perspectives on scaling solid-state lasers are unknown.

Before we discuss how the Chinese Academy of Sciences method works, let's recap the de facto industry-standard method of creating light with a 193-nm wavelength used by ASML, Canon, and Nikon for their DUV litho machines. Also, keep in mind that the CAS system is in its early stages of development, and we are talking about a test vehicle at best.

Traditional approach

DUV lithography machines by ASML, Canon, and Nikon generate 193-nm light using an argon fluoride (ArF) excimer laser. The laser chamber contains a gas mixture of argon and fluorine and a buffer gas like neon. When high-voltage electrical pulses are applied, the argon and fluorine atoms become excited and briefly form an unstable molecule called ArF (or excimer), which quickly returns to its ground state, releasing a photon with a wavelength of 193 nm.

The laser emits these photons as short, high-energy pulses at an output power of up to 100W—120W and at frequencies between 8 kHz and 9 kHz for modern immersion DUV tools. The 193-nm beam is then directed through an optical system that shapes, guides and stabilizes the light. It passes into the lithography scanner, where it shines through a photomask containing the chip pattern.

The CAS approach

The test device developed by the Chinese Academy of Sciences generates 193 nm light using a fully solid-state approach, avoiding gas-based excimer lasers entirely. It begins with a homemade Yb:YAG crystal amplifier, which produces a 1030-nm laser beam. This beam is then split into two optical paths, each undergoing a different optical process to create the components needed for 193-nm generation.

In the first path, the 1030-nm beam is converted into a 258-nm beam through fourth-harmonic generation (FHG, a nonlinear optical process that transforms a laser beam to one-fourth of its original wavelength, in this case, a 258-nm beam). This part delivers an output power of 1.2 W. In the second path, the other half of the 1030-nm beam is used to pump an optical parametric amplifier, resulting in a 1553-nm beam with a power of 700 mW.

These two beams — 258 nm and 1553 nm — are combined in cascaded lithium triborate (LBO) crystals to generate a coherent light with a 193 nm wavelength with an average power of 70 mW operating at a frequency of 6 kHz. CAS says that the test system has a linewidth narrower than 880 MHz, a performance comparable in spectral purity to that of commercial systems used today.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

A comparison?

The CAS system produces 193 nm light using a solid-state laser with a 70 mW average power and a 6 kHz frequency, achieving a narrow linewidth below 880 MHz. The test system's output is orders of magnitude lower than ASML's ArF excimer-based production systems, which deliver 100 – 120W at a 9 kHz frequency.

While the initial CAS system demonstrates capabilities, its low power output makes it unsuitable for commercial semiconductor manufacturing, where high throughput and process stability are essential. It's likely that multiple generations of development would be needed to make this a viable chipmaking light source.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0